This post can be edited by most users to provide up-to-date information about developments of this thread based on user responses, and user findings. Feel free to add, change or remove information shown here as it becomes available. This includes new coupons, rebates, ideas, thread summary, and similar items.

Once a Thread Wiki is added to a thread, "Create Wiki" button will disappear. If you would like to learn more about Thread Wiki feature, click here.

expiredjk6812 | Staff posted Sep 25, 2024 05:28 PM

Item 1 of 5

Item 1 of 5

expiredjk6812 | Staff posted Sep 25, 2024 05:28 PM

Refurb: Creality Ender 3 V3 SE FDM 3D Printer + 2-Yr Warranty

+ Free Shipping$103

$139

25% offeBay

Visit eBayGood Deal

Bad Deal

Save

Share

Leave a Comment

Top Comments

59 Comments

Sign up for a Slickdeals account to remove this ad.

I think the build plate is great. I haven't looked at the spacers. My gantry seems pretty stable, but maybe I just don't know what stable looks like.

It prints great so far

Our community has rated this post as helpful. If you agree, why not thank VSeven

I think the build plate is great. I haven't looked at the spacers. My gantry seems pretty stable, but maybe I just don't know what stable looks like.

It prints great so far

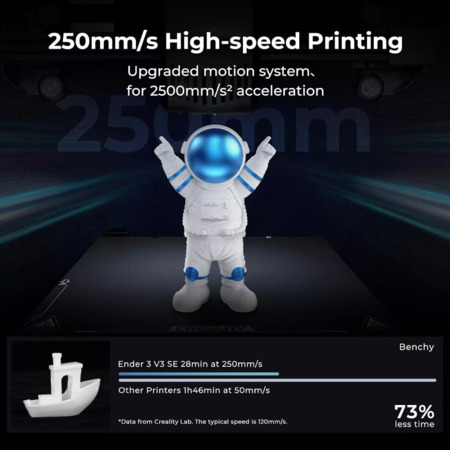

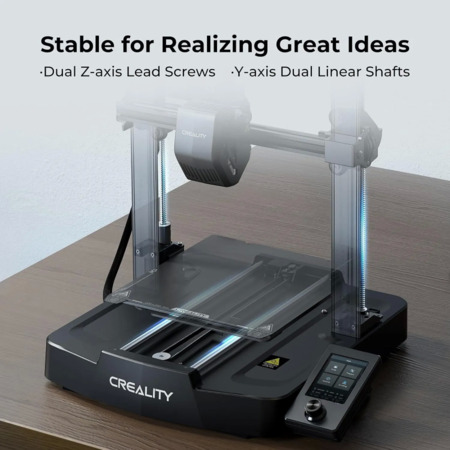

Take a level and compare the level of your base to the bed and the gantry. Or use a square against the base and gantry, see how close to 90* it is. Mine is off by about 1 1/2* which makes taller prints slightly lean. It also wobbles a bit front to back especially printing things fast. With the mods I've done (linear rails+speed plate) I'll print walls at 100mm/s and infill at 250mm/s so it gets bouncy when the bed is quickly moving front to back. Some of that you can eliminate by moving the spool off (less weight at the top) but not all. I was going to do the same gantry mod as I did with the SE which is 100% easier and worked fine but I want a cleaner look from the front so going to try this one this time around. As mentioned you could also just remove the spool and do a mod like this: https://makerworld.com/en/models/651537

Also I use Cura, I can't stand Creality's slicer. The only advantage it has is directly connecting to the KE but since you can import files by connecting to the web interface of the printer I just do that. Creality slicer is just a fork of Cura anyway and is always a few versions behind. Newest version of Cura has a profile for the KE built in. It's a little harder to use but you can do a lot more with it.

I have the V3 SE and I have just been using Cura with it.

What benefits do I get by using Creality slicer over Cura?

Isn't Creality slicer just a reskin of Cura?

Do you need to have an online printer like the KE to take advantage of these "automatic" features?

I have been getting on well with the SE and Cura and it was really easy to get started with with the auto Z offset

I have the V3 SE and I have just been using Cura with it.

What benefits do I get by using Creality slicer over Cura?

Isn't Creality slicer just a reskin of Cura?

Do you need to have an online printer like the KE to take advantage of these "automatic" features?

I have been getting on well with the SE and Cura and it was really easy to get started with with the auto Z offset

Example: I find a model I like and want to print it, first I download it. Then I open my slicer and load the file. I then need to decide things like orientation, material settings (this is typically easy as I normally use PLA), if I want a small/slow or big/fast layer thickness. I also need to think about supports etc. Once I have that done I can load the file onto an SD card and plug it into the printer and hit go. So even though the printer part was really simple, the other steps weren't. With a basic networked printer you save the steps from after you slice the model to where you load it on the printer. That is nice and if my printer weren't near the computer I would really consider it.

What Bambu has done is setup their file sharing site so the files are "pre-sliced". It might just be some Bambu server looks at your printer config and then quickly slices the files for your printer or perhaps when you upload a file they pre-slice it for each model they sell. Regardless, the magic is you don't have to download the file to your slicer then do all the slicer decision making. Instead, the file goes right to your printer with all the slicer/support/orientation choices made automatically. This is part of why you can pick a model from your phone then print it at home without using a slicer. I can see why this appeals to people.

I sounds like Creality is trying to match this functionality with their newer printers. This might be why they switched from Cura to a fork of Prusa slicer. It might be better for networking or better integration with a web store setup.

If your primary interest is printing your own models then a lot of this isn't a value add. Also, if you are one of those curmudgeons

I like driving stick shift cars even though automatics are "better". I don't mind downloading and making decisions how I slice the files and I seem to stick to using thumb drives for file transfer...

Sign up for a Slickdeals account to remove this ad.

Example: I find a model I like and want to print it, first I download it. Then I open my slicer and load the file. I then need to decide things like orientation, material settings (this is typically easy as I normally use PLA), if I want a small/slow or big/fast layer thickness. I also need to think about supports etc. Once I have that done I can load the file onto an SD card and plug it into the printer and hit go. So even though the printer part was really simple, the other steps weren't. With a basic networked printer you save the steps from after you slice the model to where you load it on the printer. That is nice and if my printer weren't near the computer I would really consider it.

What Bambu has done is setup their file sharing site so the files are "pre-sliced". It might just be some Bambu server looks at your printer config and then quickly slices the files for your printer or perhaps when you upload a file they pre-slice it for each model they sell. Regardless, the magic is you don't have to download the file to your slicer then do all the slicer decision making. Instead, the file goes right to your printer with all the slicer/support/orientation choices made automatically. This is part of why you can pick a model from your phone then print it at home without using a slicer. I can see why this appeals to people.

I sounds like Creality is trying to match this functionality with their newer printers. This might be why they switched from Cura to a fork of Prusa slicer. It might be better for networking or better integration with a web store setup.

If your primary interest is printing your own models then a lot of this isn't a value add. Also, if you are one of those curmudgeons

I like driving stick shift cars even though automatics are "better". I don't mind downloading and making decisions how I slice the files and I seem to stick to using thumb drives for file transfer...

Also have no problem with using the cloud.

And I have never used any CAD software but want to learn if I can ever even make a decision on which one to pick.

But I don't think that the Bambu site will have all models pre-sliced.

There are lots of sto 3mf files and I doubt they have very many compared to what is out there.

I am now actually considering a Bambu A1 w/AMS lite

For some reason I thought the build volume was still smaller on the A1 not just the A1 mini but after checking again I see it is actually larger in all 3 directions.

Plus AMS lite wastes less filament than the regular Bambu AMS

The K2 is too expensive and there is still no word when their AMS will be released.

I hear Bambu might be releasing a multi tool head machine like the prussa max.

In November and the A1 is sold out at my Microcenter both alone and the bundle.

I should probably wait it out more but if it was a KE for that price I would have jumped.

Direct drive extruder is better when dealing with details that require the extruder to start stop. The SE is quite a bit faster. It also has auto bed leveling and auto z offset. The control panel is easier to work with and the SD card vs micro SD card is easier to load. Critically, it's easier to get a good print out of the SE.

I know the se is a little different but the bones are mostly the same. This seems like a very good deal.

Also have no problem with using the cloud.

And I have never used any CAD software but want to learn if I can ever even make a decision on which one to pick.

But I don't think that the Bambu site will have all models pre-sliced.

There are lots of sto 3mf files and I doubt they have very many compared to what is out there.

I am now actually considering a Bambu A1 w/AMS lite

For some reason I thought the build volume was still smaller on the A1 not just the A1 mini but after checking again I see it is actually larger in all 3 directions.

Plus AMS lite wastes less filament than the regular Bambu AMS

The K2 is too expensive and there is still no word when their AMS will be released.

I hear Bambu might be releasing a multi tool head machine like the prussa max.

In November and the A1 is sold out at my Microcenter both alone and the bundle.

I should probably wait it out more but if it was a KE for that price I would have jumped.

Our community has rated this post as helpful. If you agree, why not thank zeekworld

Perhaps you had a better experience buying "refurbished" from this store but not me.

I did get a response via eBay messages three days later with some apologies a return label and I am now waiting a full refund. A great waste of time.

Just a heads up, eBay store reviews are all over the place, I should have read them before purchasing the printer, my fault.

Sign up for a Slickdeals account to remove this ad.

Leave a Comment