popularMaroonDeer2762 posted Jan 23, 2026 07:08 PM

Item 1 of 6

Item 1 of 6

popularMaroonDeer2762 posted Jan 23, 2026 07:08 PM

Siraya Tech Fibreheart PPA-CF 3D Printing Filament - Extreme Performance 15% Carbon-Fiber Filled for Engineering / Functional Parts

$52

$70

25% offAmazon

Get Deal at AmazonGood Deal

Bad Deal

Save

Share

Leave a Comment

13 Comments

Sign up for a Slickdeals account to remove this ad.

https://youtu.be/w7JperqVfXI?si=

https://youtu.be/w7JperqVfXI?si=

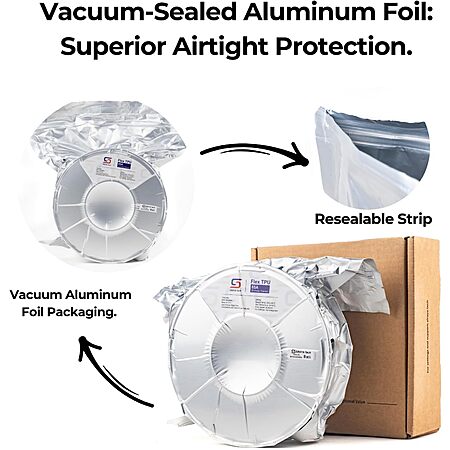

EDIT: nylon and other polyamides do need two things to be printed well: HIGH heat (that 300* on the box is no joke) and VERY Dry. If you don't have a dryer that can spool out while printing, you'll probably end up with stringing in a couple hours if the RH% is above 25-30.

https://youtu.be/w7JperqVfXI?si=

https://youtu.be/w7JperqVfXI?si=

https://youtu.be/w7JperqVfXI?si=

Sign up for a Slickdeals account to remove this ad.

EDIT: nylon and other polyamides do need two things to be printed well: HIGH heat (that 300* on the box is no joke) and VERY Dry. If you don't have a dryer that can spool out while printing, you'll probably end up with stringing in a couple hours if the RH% is above 25-30.

In the case of PPA, it offers high(-ish/-er) temperature usage and good hoop stress (extrusion axis) strength. I'm hoping to try it out for rocket engine casings. The eSun PAHT-CF I have is brutal to print with due to moisture sensitivity but produces amazing parts. The Fiberon PET-CF I have is not as strong as the PA-CF, but the filament is so rigid I've had the filament snap in my extruder during retraction. It makes nice, stiff parts but the cross-layer cohesion is relatively poor. If the PPA can buy me another 20-30C HDT, have z-axis strength like PA, and be as stiff or better than the other two, it would be a win for the right components.

Filler (CF or GF) definitely has some advantages, just not necessarily in the strength department. Often I don't need additional strength, I need stiffness. I picked up some cheap ($10/kg) PETg-CF and the stiffness increase "fixes" one of the major downsides to printing in PETg - low modulus.

In the case of PPA, it offers high(-ish/-er) temperature usage and good hoop stress (extrusion axis) strength. I'm hoping to try it out for rocket engine casings. The eSun PAHT-CF I have is brutal to print with due to moisture sensitivity but produces amazing parts. The Fiberon PET-CF I have is not as strong as the PA-CF, but the filament is so rigid I've had the filament snap in my extruder during retraction. It makes nice, stiff parts but the cross-layer cohesion is relatively poor. If the PPA can buy me another 20-30C HDT, have z-axis strength like PA, and be as stiff or better than the other two, it would be a win for the right components.

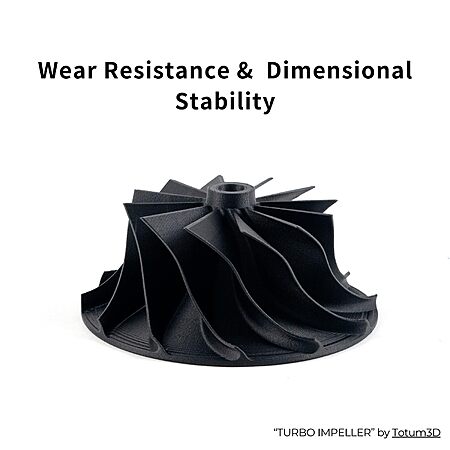

CF and GF fiber loading is for Stiffness and Heat Resistance. If your favorite YouTube is checking the differences in strength and not stiffness/creep resistance/heat resistance/or even printability, they've lost the plot.

Your small reminder that cf/gf loading does a hell of a lot more for semi-crystaline materials like PPA than it does for amorphous materials like petg, due to it acting like a nucleating agent, allowing for higher crystalinity in the material.

Leave a Comment