expireddavid3808 posted May 22, 2021 08:19 PM

Item 1 of 5

Item 1 of 5

expireddavid3808 posted May 22, 2021 08:19 PM

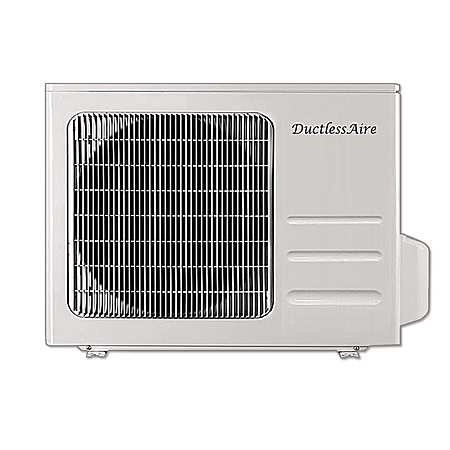

DuctlessAire 12 Seer 12000 BTU 220V 1-Ton Ductless Mini Split Air Conditioner

+ Free Shipping$779

Home Depot

Visit Home DepotGood Deal

Bad Deal

Save

Share

Leave a Comment

Top Comments

This works if you're handy since you'll probably do a better job. Doing things like a nitrogen pressure test, which aren't stated in the manual, is a good practice that many installers will skip unless it's explicitly stated in the manual like in some Mitsubishi units. This practice makes sense for heat pump R410A units which will see upwards of 450 psi on the head when in heat pump mode. But expect to spend $500-$700 on tools if you want to do it right.

Edit: if you want me to comment more on the tools I went with, let me know.

Edit Edit: As promised, I posted my tools breakdown reply on #99 of this thread, but I'm also going to post it below too. If this angers the mods then please remove post #99.

Everyone can decide what you need for your install versus others, but here's the tools that I bought for mine:

Nitrogen Tank w/ Regulator (got on Craigslist)1 $ 100.00

Appion CTEE14 MegaSeal Low-Loss Charging T-Fitting - 1/4'1 $ 49.94

Appion MGAVCR Mega Flow Vacuum Rated Valve Core Removal Tool – 5/16" System Connection1 $ 48.48

CPS VG200: Vacuum Micron Gauge with Digital LCD Display1 $ 146.21

Refrigeration Technologies RT201B Nylog Gasket/Thread Sealant1 $ 10.25

Yellow Jacket 42004 Series 41 Manifold with 3-1/8" Gauge, psi, R-22/404A/410A1 $ 112.29

Yellow Jacket 19173 R-410 5/16" to 1/4" coupler w/ schrader valve.1 $ 14.26

CPS Pro-Set R410A Flare Gauge1 $ 19.81

CPS BLACKMAX BFT850 Ultra-Lightweight R-410A Clutch-Type Ecentric Flaring Tool1 $ 130.03

Reed Tool DEBO Pencil Shape Deburring Tool for Copper1$11.68

RIDGID 32975 Model 103 Close Quarters Tubing Cutter, 1/8-inch to 5/8-inch Tube Cutter , Silver , Small1$12.67

Johnsen's 6915 Vacuum Pump Oil - 12 oz.1 $ 9.79

PITTSBURGH AUTOMOTIVE 3 CFM Two Stage Vacuum Pump1 $ 149.99

PITTSBURGH 3/8 In. Metric Crowfoot Wrench Set, 7 Pc.1 $ 9.99

For mine, it was a total of $825-ish, with it being more like $900 after tax. But I bought multiple things that most people don't need to buy, marked in italics, so you can save a lot of money skipping these. These optional tools represent an additional $372.61 ($400.55 after tax, at least where I live) you can eliminate about 50% from the tools budget.

First and foremost, don't attempt to work with electrical or HVAC unless you're pretty comfortable with DIY projects.

The Nitrogen tank is optional for pressure testing. Some say if you can pull a good vacuum and let it sit for a while that is "good enough" and most company's instructions exclude this from the installation instructions. But it's worth considering because when running R-410A in heat pump mode, you'll get high pressure across your head side of the loop. This makes sense because the high-pressure side = heat. So in my head it made sense you'd want to do a pressurization test and a vacuum down test, since one is pushing apart the fittings (pressure) and the other is sucking them together (vacuum). Since the fittings will all be exposed to both types of pressures it makes sense for me. Follow Dakine or Mitsubishi installation manual instructions for nitrogen pressure testing if you opt to do it. Note that most professional installers WILL SKIP THIS unless it's a unit that requires it (think Mitsubishi) and the installer is one of their "diamond" approved installers or whatever.

Secondly, I bought a flaring tool because I had a 2-head system and cut the tubing to fit the installation and make it more tidy. This is optional and I do not recommend it unless you know what you're doing. It also saves money to skip this. Before cutting, you need to make sure your run or runs have the required length to prevent overcharging the system. If you have a single head unit and end up cutting the tubes to 1/2 the length you may have too much refrigerant in the linesets. Refer to your manual or talk to the company before you decide to do this. And if you decide to do it anyways, yes it must be a HVAC specific flaring tool. Get one with the clutch system to prevent overtightening the flare press and make it foolproof. R-410A runs at too high of pressures to get away with subpar flares. Deciding to just accept the standard length of the copper tubing eliminates the costs associated with the Flaring tool, flaring gauge, deburring tool, and pipe cutting tool.

As for the rest, you do not NEED a digital micron gauge, many just use their normal gauge set's low pressure side gage and watch to see if the needle moves. This will also work. Again I wanted to go with professional duty equipment to get an install I'm 100% confident in. That way if the thing dies in a few years I won't have wonder in the back of my mind whether I screwed up the install. I know 100% my install was perfect. I went with the Yellow Jacket brand gauges, although you could in theory just get the low side gauge, hose, and valve if you're just pulling vacuum and save some money. I'm sure the garden variety chinesium brand gauges are probably perfectly fine for a solo install and will cut the cost in half for them.

The Appion Schrader core removal tool and the t-valve are totally optional too. You'd have to do some youtubing to see how they're used, but here's a great video which shows essentially the same setup I bought: https://www.youtube.com/watch?v=81EeY7S

But you can skip those tools and just use the Yellow Jacket 5/16" to 1/4" adapter and be just fine without them. Your pressure drawdown will just take a bit longer since you're going through the Schrader valve, and you'll loose a tiny bit of refrigerant before the schrader valve closes. Skipping these tools will save you $130-$140.

For the vacuum pump I went with a harbor freight 3CFM rated 2-stage vacuum pump. I believe it's rated for sub-30 microns of vacuum which is great, and a review on their site showed a guy pulling 13 microns if I recall correctly. To put this into perspective most manufacturers suggest pulling below 500 microns before charging the system. This is slightly overkill but it works for me.

Lastly I already have a torque wrench but you can get them dirt cheap from harbor freight, and I bought some crowfoot wrenches to use with my torque wrench to torque the bolts to the manufacturer's specifications. Will it really matter if you don't do it to spec? I don't know but I'm not finding out.

Then beyond all of this you'll have to run some 220-240v and have a disconnect box by your run. If you're not a confident DIY'er don't go for this, but if you are then just watch plenty of videos of installations, follow the instructions, and you'll be fine.

Pros-

No duct work is obvious.

On demand which can save heating/cooling bill.

More precise temperature control "zones".

Cons-

The zones play as double edge sword, when moving in or out the heated/air conditioned space takes some getting used to.

The indoor unit hangs on the wall compare to just a register, so the wall is more or less occupied.

Have to run additional electricity to both in door and outdoor units and the tubes from the indoor unit to the outdoor unit.

More filters to clean.

168 Comments

Sign up for a Slickdeals account to remove this ad.

It is like wipe your ass half way after poop and pull up the pants

Pros-

No duct work is obvious.

On demand which can save heating/cooling bill.

More precise temperature control "zones".

Cons-

The zones play as double edge sword, when moving in or out the heated/air conditioned space takes some getting used to.

The indoor unit hangs on the wall compare to just a register, so the wall is more or less occupied.

Have to run additional electricity to both in door and outdoor units and the tubes from the indoor unit to the outdoor unit.

More filters to clean.

Comparing the 9000 to 12000 BTU models, the 12000 is quieter and has a variable speed inverter for the heat pump (for $80 more).

I'd prefer the 12000 model but it's oversized for my basement room (~300 sq ft). How bad of an idea is it to install the oversized 12000 BTU model? Can I expect freezing coils, etc. like with a standard window AC?

The Mr. Cool units do not have anything in the linesets either. The only difference is the Mr. Cool linesets are vacuumed and sealed and have valves which open up when you connect them. So, you do not need to vacuum the Mr. Cool units. The rest of the lot has open lines and once you connect them, you still have to vacuum the lines regardless of if you cut them or not.

The reason Mr. Cool lines can't be cut is because of the special valves at each end which keep the lines sealed during shipment.

The Mr. Cool units do not have anything in the linesets either. The only difference is the Mr. Cool linesets are vacuumed and sealed and have valves which open up when you connect them. So, you do not need to vacuum the Mr. Cool units. The rest of the lot has open lines and once you connect them, you still have to vacuum the lines regardless of if you cut them or not.

The reason Mr. Cool lines can't be cut is because of the special valves at each end which keep the lines sealed during shipment.

Sign up for a Slickdeals account to remove this ad.

These ac compressors are not meant to run 24/7 ever. IF you do , the unit is WAY too small.

Also, since it's a basement it probably won't gain a lot of heat and the ac will run very infrequently.

Cold and clammy completely depends on the climate. Cold and clammy is because the ac doesn't get time to remove the moisture but does have time to cool it down (too quickly). So the moisture actually stays in the room. Going from 8K to 12K isn't going to cause that.

These ac compressors are not meant to run 24/7 ever. IF you do , the unit is WAY too small.

Also, since it's a basement it probably won't gain a lot of heat and the ac will run very infrequently.

Cold and clammy completely depends on the climate. Cold and clammy is because the ac doesn't get time to remove the moisture but does have time to cool it down (too quickly). So the moisture actually stays in the room. Going from 8K to 12K isn't going to cause that.

1st, 12k is massive for 300 sq ft (obviously I don't know his load or what he has in there, but a quick manual j for my area puts it at about 2,000 btu's.)

2nd, almost all basements already have a high RH and when you start cooling it it gets worse unless the unit runs long enough to remove it. Short cycling will make it worse.

3rd, this is an INVERTER COMPRESSOR. You might want to read up on them. They ARE designed to run all the time. I couldn't find the exact specs for this unit, so I don't know what the minimum flow is. They also don't specify if they use some type of fuzzy control or a basic delta T. So it is possible that their lowest flow is still fairly high. But nevertheless it's designed to keep running.

https://www.anracelectr

The Mr. Cool units do not have anything in the linesets either. The only difference is the Mr. Cool linesets are vacuumed and sealed and have valves which open up when you connect them. So, you do not need to vacuum the Mr. Cool units. The rest of the lot has open lines and once you connect them, you still have to vacuum the lines regardless of if you cut them or not.

The reason Mr. Cool lines can't be cut is because of the special valves at each end which keep the lines sealed during shipment.

Sign up for a Slickdeals account to remove this ad.

Leave a Comment