expiredLovelyCheetah | Staff posted Jul 23, 2024 11:03 PM

Item 1 of 8

Item 1 of 8

expiredLovelyCheetah | Staff posted Jul 23, 2024 11:03 PM

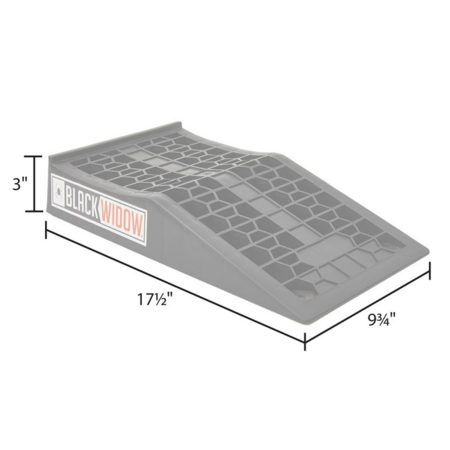

Black Widow Plastic Low Profile Car Ramps (Pair, 10,000lb Capacity)

+ Free Shipping$24

$30

20% offDiscount Ramps

Visit Discount RampsGood Deal

Bad Deal

Save

Share

Leave a Comment

Top Comments

3" lift height is way too low to be of much use though. I have a bunch of low/sporty cars that i use plastic low-profile ramps on for routine maintenance, and they usually provide more like 6-8" of height. The peak height of a ramp isn't the main thing that makes low profile ramps work.... it's the length and angle of the slope which allows the front lip and other low parts of the vehicle to clear the ramp without hitting anything.

"Honey, look what I got you for a present! Can you change my oil?" 🕷️

Use jack stands (edit: with your ramps), everyone!

102 Comments

Sign up for a Slickdeals account to remove this ad.

Add a lip at the end of the ramp and you won't drive off.

But I could see people using this on low profile vehicles just to be able to get a floor jack underneath. I've had to drive up on 2x6 before to do that so this would be nice alternative.

Sign up for a Slickdeals account to remove this ad.

Yeah... when I first read this guy's post about DIY 3d printed ramp/ramps... my first thought was... he better use (sturdy steel) jack stands when using his DIY ramps 100% of time.

Yes, lots of hobbyist makers print many types of, say, carabiners. Just depends on what you use it for- keys or spelunking.

Concrete works with rebar (and meshes such as chicken wire) to gain advantages of both, especially as concrete tends to crumble/crack.

Some parts of the plastic webbing pockets underneath this ramp may be too small to stop splitting towards crunching the concrete "mini-blocks".

CSA concrete, along with many other additive-types that address shrinkage/cracking, might be a contender to fill the narrower pockets. Resins might work, too, now that we're talking about another weight-class for ramps.Just dont drop it...

Sign up for a Slickdeals account to remove this ad.

Even if one can hand-pick straight flat/quarter-sawn wood and apply the _correct orientation, the laws of physics will find nature's faulty lines- at the most inopportune time.

There's a reason why US/OSHA requires scaffolding boards to be certified (Asia's bamboo scaffolds notwithstanding- they might be better than random planks).

Perhaps cut an uncompromised section off a scrap Glulam/LVL beam- nobody in construction wants the liability of used/broken LVL, should be super-cheap? Maybe at one of those reclaimed lumber stores? Borrow Grandpa's mondo bandsaw?

Edit: More DIY - cut and stack a bunch of plywood (minimum voids, so Marine/CCX/etc) with the proper resin/epoxy adhesive, and compress it with the force of, dunno, a car running over it?

Leave a Comment