frontpagephoinix | Staff posted Yesterday 08:25 AM

Item 1 of 3

Item 1 of 3

frontpagephoinix | Staff posted Yesterday 08:25 AM

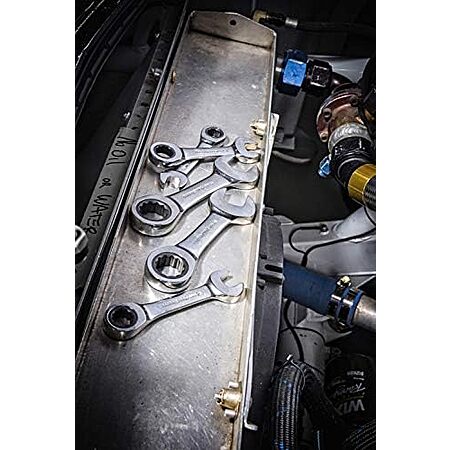

34-Piece GEARWRENCH Standard & Stubby Ratcheting Wrench Set (SAE/Metric)

+ Free Shipping$86

$140

38% offAmazon

Get Deal at AmazonGood Deal

Bad Deal

Save

Share

Leave a Comment

9 Comments

Sign up for a Slickdeals account to remove this ad.

Our community has rated this post as helpful. If you agree, why not thank Griffbiff

One) Regular combination wrenches traditionally have a 15° offset on the box end of a wrench. This 15° offset has been the industry standard for decades and decades, and is considered the best middle ground for accessing bolts with the box end. It allows for space for your fingers when holding the wrench. With a non-reversible ratchet wrench you can't have the offset because you have to be able to flip it.

https://images.tekton.c

Two) if you were backing out a bolt with a non-reversing ratchet and wrench, and that bolt runs into an obstruction, now there is no way to reverse directions because you need to flip the wrench, but you can't get the wrench off of the bolt because of the obstruction. You might be able to bring the ratchet end down the shank and then get another open end wrench in there to manually drive it back in, but if that's not possible, you have to cut the bolt to get your wrench back.

I personally ran into this situation and ended up breaking a $40 sensor to get my wrench back because I preferred that to cutting the bolt. It permanently soured me to non-reversible ratchet, wrenches.

Edit: Some typos and added a link.

Sign up for a Slickdeals account to remove this ad.

People always get bent out of shape when I say this, but there are two major reasons you want an actual reversing rating wrench (yes- with a switch like a ratchet), as opposed to one of these. The trade-offs may not matter to you and so go ahead and buy them, but it's better to know.

One) Regular combination wrenches traditionally have a 15° offset on the box end of a wrench. This 15° offset has been the industry standard for decades and decades, and is considered the best middle ground for accessing bolts with the box end. It allows for space for your fingers when holding the wrench. With a non-reversible ratchet wrench you can't have the offset because you have to be able to flip it.

https://images.tekton.c

Two) if you were backing out a bolt with a non-reversing ratchet and wrench, and that bolt runs into an obstruction, now there is no way to reverse directions because you need to flip the wrench, but you can't get the wrench off of the bolt because of the obstruction. You might be able to bring the ratchet end down the shank and then get another open end wrench in there to manually drive it back in, but if that's not possible, you have to cut the bolt to get your wrench back.

I personally ran into this situation and ended up breaking a $40 sensor to get my wrench back because I preferred that to cutting the bolt. It permanently soured me to non-reversible ratchet, wrenches.

Edit: Some typos and added a link.

Leave a Comment