The Home Depot [homedepot.com] has

15 Amp Corded 10 in. Job Site Table Saw with Rolling Stand for

$549.

Shipping is Free

Product Description from Store

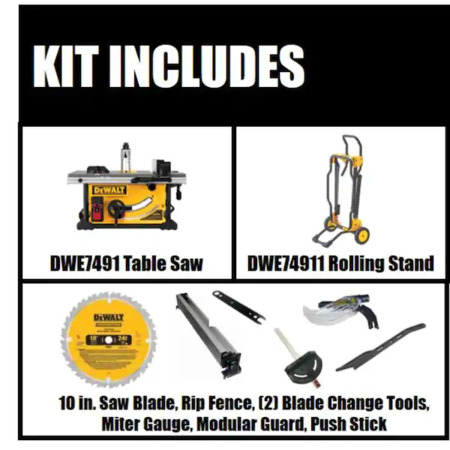

The DEWALT DWE7491RS offers you greater mobility by pairing a DEWALT table saw with a rolling stand. This 10 in. jobsite table saw is powered by a 15 Amp motor with a 32-1/2 in. rip capacity that lets you cut larger shelving, trim boards, and hardwoods with ease. A rack and pinion fence system makes fence adjustments fast, smooth and accurate. The rolling table saw stand is designed for easy set up and break down with excellent stability.

- Patented material support, can be used for narrow rip cuts

- 32-1/2 in. rip capacity easily cuts a variety of larger shelving and trims materials

- Push button release design eliminates air blow back when connecting and disconnecting

- 1-handed loading 1/4 in. hex chuck accepts 1 in. bit tips

- 2 in. dust collection port easily connects to a vacuum for efficient dust extraction

- 3-1/8 in. depth of cut at 90 degree and 2-1/4 in. at 45 degree

- 26-1/4 in. x 22 in. table provides superior material support

Leave a Comment

12 Comments

Sign up for a Slickdeals account to remove this ad.

Our community has rated this post as helpful. If you agree, why not thank LivelyHill1179

This tool has been a beast. Having progressed in the field, I have learned that the things I have demanded of this tool on a regular basis are... not normal for a "job site" saw. I routinely work walnut, hard maple, white oak, pecan, brazilian tigerwood, and ipe (the latter two famously freakishly hard [and toxic, dust collection is a good thing]).

If precision is important to you (precision should be important to you)...

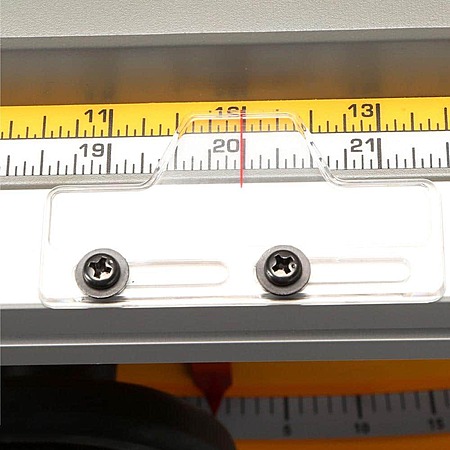

- Have a proper try-square handy to check for 90 regularly, especially after folding/unfolding your saw, or messing with the dust collection

- Do not count on the aluminum fence for a 90-degree reference to the table (on this or any job-site saw)

- The DeWalt throat plate is sloppy and impossible to keep perfectly flush. Get (or make) a zero-clearance plate. Actually, get a few. One for 90-degree cuts, and others for dados. Keep the Dewalt plate for beveled cuts.

- The miter gauge (as with all in-the-box gauges) is not good. You will eventually want one from people who make them. The subject of miter gauges can be weirdly controversial for some reason (can they replace a sled? which brand? do they suck?) So I won't even start something by saying out loud that for me it's yes/Incra/no.

- Keep the junky miter gauge to screw spoilboards to for odd zero-clearance work.

This tool has been a beast. Having progressed in the field, I have learned that the things I have demanded of this tool on a regular basis are... not normal for a "job site" saw. I routinely work walnut, hard maple, white oak, pecan, brazilian tigerwood, and ipe (the latter two famously freakishly hard [and toxic, dust collection is a good thing]).

If precision is important to you (precision should be important to you)...

- Have a proper try-square handy to check for 90 regularly, especially after folding/unfolding your saw, or messing with the dust collection

- Do not count on the aluminum fence for a 90-degree reference to the table (on this or any job-site saw)

- The DeWalt throat plate is sloppy and impossible to keep perfectly flush. Get (or make) a zero-clearance plate. Actually, get a few. One for 90-degree cuts, and others for dados. Keep the Dewalt plate for beveled cuts.

- The miter gauge (as with all in-the-box gauges) is not good. You will eventually want one from people who make them. The subject of miter gauges can be weirdly controversial for some reason (can they replace a sled? which brand? do they suck?) So I won't even start something by saying out loud that for me it's yes/Incra/no.

- Keep the junky miter gauge to screw spoilboards to for odd zero-clearance work.

BUT a fence should arguably just be your width reference, not your square reference. If you can

- Make one consistent face on your material (practice and outfeed control)

- Dial your blade in to perfect 90

then you put that cut face down and the table itself is all the angular reference you need, with the fence controlling your width.The first things I suggest for anyone getting a table saw or struggling with one are always a good machinists try square for 90s, a magnetic angle finder (mine's a Klein) for all other blade angles, and a proper (or at least an improved) miter gauge. Those three things alone - with regular checking - can turn any saw into a precision tool.

This tool has been a beast. Having progressed in the field, I have learned that the things I have demanded of this tool on a regular basis are... not normal for a "job site" saw. I routinely work walnut, hard maple, white oak, pecan, brazilian tigerwood, and ipe (the latter two famously freakishly hard [and toxic, dust collection is a good thing]).

If precision is important to you (precision should be important to you)...

- Have a proper try-square handy to check for 90 regularly, especially after folding/unfolding your saw, or messing with the dust collection

- Do not count on the aluminum fence for a 90-degree reference to the table (on this or any job-site saw)

- The DeWalt throat plate is sloppy and impossible to keep perfectly flush. Get (or make) a zero-clearance plate. Actually, get a few. One for 90-degree cuts, and others for dados. Keep the Dewalt plate for beveled cuts.

- The miter gauge (as with all in-the-box gauges) is not good. You will eventually want one from people who make them. The subject of miter gauges can be weirdly controversial for some reason (can they replace a sled? which brand? do they suck?) So I won't even start something by saying out loud that for me it's yes/Incra/no.

- Keep the junky miter gauge to screw spoilboards to for odd zero-clearance work.

Sign up for a Slickdeals account to remove this ad.

The saw and stand come together in the same box. The stand is definitely built just for this tool. Which makes sense. For some job-site table saws, they are small enough that a stand is optional. This one is big enough to require one (until you make your own, as mentioned above). Its footprint would be a little large for any universal stands for smaller job-site saws. As such, it just has to come with one to be usable out of the box. I have not seen this stand for sale separately, or used for any other purpose with any other tool.

Taken a step further by way of example, if you had a busted stand out of the box, I'd bet you a brand new shiny out-of-the-box DeWalt miter gauge that they'd have you swap the saw and all.

I have never once even attached the blade shroud kickback pawl doodad. Dust collection just from underneath does the trick a lot of the time. If ever I needed additional dust collection from above, it would be when I'm just shaving a face (table saw jointing, glue line ripping, etc.) and would want an unobstructed view of what I'm doing anyway.

And I'll be honest with you. Don't tell anybody. I haven't used a riving knife in years. So according to the web commentariat, I believe that means that I am a menace and everything I said above is totally wrong and everyone should believe the opposite.

Leave a Comment